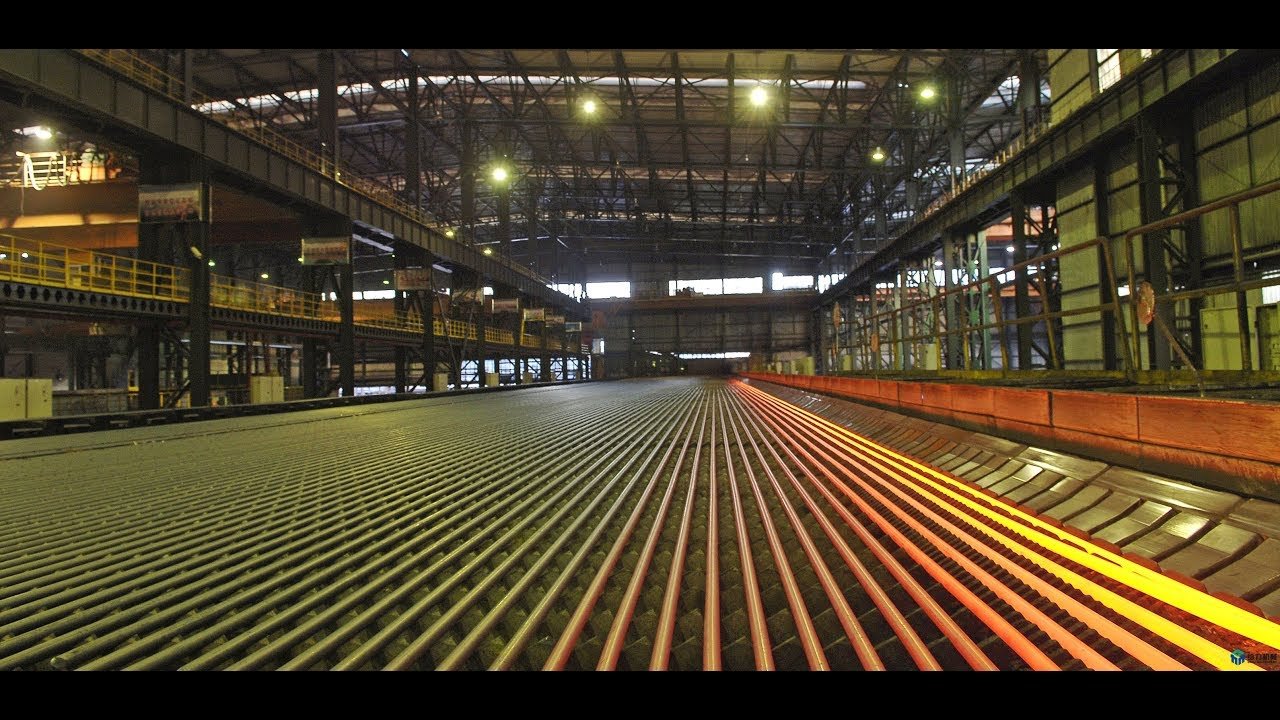

Automatic Cooling Beds

Cooling beds naturally cool the material by one pitch for every rake movement to impart straightened material. It helps improve the metallurgical properties as the bars are cooled uniformly.

Cooling bed entry can be completed with lifting aprons and natural braking or twin channel and mechanical braking.

Features:

- Straightness of bar delivered from cooling bed shall be within 2 mm per metre & 6 mm per metre in 12 mtr length.

- Designs available for handling production capacity from 25 Ton per Hour to 75 Ton per Hour.

- Walking Beam Rake type cooling bed design for smooth performance. Temperature of Bar at Inlet of cooling bed – 550 to 600 C and Temperature at exit is 200 C.

- Natural cooling of the bars by air.

- Cooling bed designs available for handling re-bars, angles, flats, beams, plain rounds, channels, beams, etc.

- Aligning rollers provided for the cooling bed for proper alignment of incoming material.

- Layer transfer mechanism also provided for shifting of collected re-bars onto the cold shear run in roller table.

- More than 15 successful installations running.